I had 5 small pumpkins and it made a lot of puree. Start by washing your pumpkins and preheating your oven to 350*. I started cutting just the pumpkin tops and putting whole pumpkins in the oven, it was taking way to long to cook. So I started cutting tops and bottoms off and quartering the pumpkins, arranged them skin side down on the pan. You also need to scrape off all the gunk; sometimes it is easier to cook the pumpkin for a little bit then scrape the gunk but you can do it before you bake it too. Make sure to set the seeds aside, they make an awesome snack. It takes at least a half hour, but more like 45 minutes to bake. You can tell it is done because the pumpkin will be soft and the skin will peel off pretty easily. The smell of pumpkin cooking is awesome and it kept me motivated to clean the house...maybe I will have to cook pumpkin once a week because cleaning is not fun.

I had 5 small pumpkins and it made a lot of puree. Start by washing your pumpkins and preheating your oven to 350*. I started cutting just the pumpkin tops and putting whole pumpkins in the oven, it was taking way to long to cook. So I started cutting tops and bottoms off and quartering the pumpkins, arranged them skin side down on the pan. You also need to scrape off all the gunk; sometimes it is easier to cook the pumpkin for a little bit then scrape the gunk but you can do it before you bake it too. Make sure to set the seeds aside, they make an awesome snack. It takes at least a half hour, but more like 45 minutes to bake. You can tell it is done because the pumpkin will be soft and the skin will peel off pretty easily. The smell of pumpkin cooking is awesome and it kept me motivated to clean the house...maybe I will have to cook pumpkin once a week because cleaning is not fun.Then into the oven...

|

| Started them skin side down... |

|

| Then flipped them |

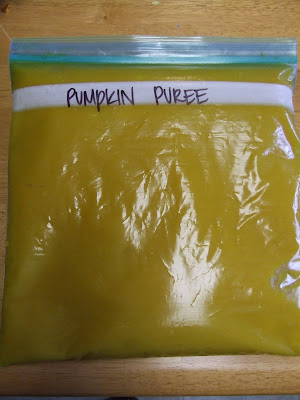

I bagged and froze most of it but set some aside to make some pumpkin chocolate chip cookies. I will make sure to tell you how they turn out.

|

| Soon to be made into cookies. |

After I finished the pumpkins, I moved onto apples. I have been wanting to do some experimenting using applesauce to replace oil in some recipes. My step father just had heart surgery and I want to make sure the things I bake for the holidays he can also eat. I made about gallon of unsweetened applesauce, bagged it and froze that as well.

|

| This will be grape jelly. |

I bagged that up, stuck it in the freezer and headed over to meet John in the garage where we made wine. That's right, after all that I even squeezed wine making into my day. This is such an interesting process and was fun to learn. I set aside of grape juice which I will use to make grape jelly at someday. We made three different batches of wine, we will try each to see which is the best way to do it next year. The first batch was just juice (that was squeezed the night before), the second was juice and pulp, and the third was juice with pulp in a bag. As far as time spent on each batch, the first was the most time consuming due to the squeezing all the juice. If it turns out the best it will be well worth the time spent. The first step is to organize yourself...must get all your ingredients and tools together as well as a copy of your recipe. The grapes we grow are a cross between a concord and a Minnesota wild grape, so John chose a recipe that works well with wild grapes and also ordered a yeast that is used for wines made with wild grapes.

Once we had everything gathered and established a plan we added the water to the first batch.

The next step is to test the acidity of the mixture. We needed the acidity to be at .65 once we achieved the acidity we could add the sugar, yeast nutrient, and the pectic enzyme. We put 2 pounds of sugar for every 1 gallon of liquid, each batch was about 5 gallons...that's 10 pounds of sugar, the yeast will have to eat something.

|

| Testing acidity |

After adding all the ingredients we then had to check the sugar density...

The last step is to add campden tablets; this kills any natural yeasts in the wine. On Tuesday we will add our yeast to it and the first fermentation will start, but for now they will sit in the garage....

And as we were finishing up and getting ready for dinner, John let me sample the wine he made last year. Can't wait to taste these batches...

No comments:

Post a Comment